Well, Let us first ask "What is Plastic made off?"

The answer is Petroleum. From here we look for an Answer to Plastic-Pollution. How about converting the waste plastic back into Oil. With this goal we begin this article.

Millions of animals are killed by plastics every year and so environmentalists all over the World are trying to reduce the amount of Plastic in the environment. A good enough process is reuse it. Unfortunately, all plastic is not recyclable and a better part is just waste.

But, there is a chemical way to reduce this waste and convert it into fuel. The method of Pyrolysis. By definition, Pyro means heat and Lysis means Breakdown, so Pyrolysis means breaking down of molecules by application of Heat. Plastic is nothing but polymers of Organic Molecules. And all molecules have a vibrational property. In Pyrolysis we use heat to increase the vibrational energy of the polymer atom to break them. It must be noted that if heating takes place in presence of oxidising materials like oxygen there is always a chance of being oxidised, so Pyrolysis must take place in a closed container.

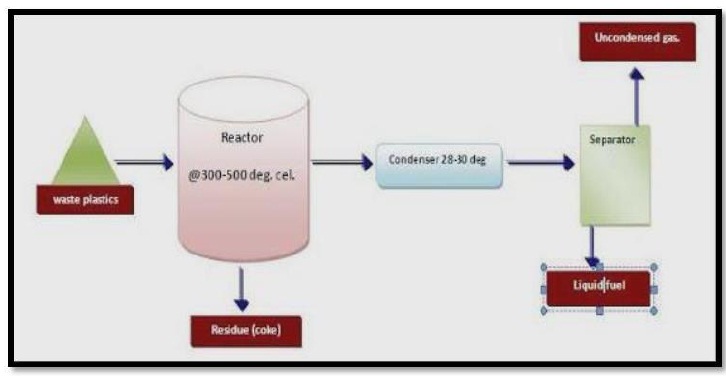

Scientist have seen that it is possible to break down waste plastic into Oil using pyrolysis in the absence of air and in presence of catalyst. Either ash or zeolite is normally used as catalyst. The steps to convert plastic to fuel are as follows:-

- Pretreatment : The foreign particle are removed from the waste plastic in this process.

- Shredder : The pre-treated plastic is then sent to a plastic shredder where it is cut into smaller pieces.

- Pyrolysis : The smaller pieces are then sent into a densifier where they are converted into a dense material to facilitate storage. Then they are sent into the Pyrolysis chamber where Pyrolysis takes place in absence of air and in presence of catalyst. Here the plastic is heated to 450 degree Celcius, which slowly melts and Evaporates.

- Condensation : The gaseous plastic or more appropriately speaking the HC gases pass through a condensation chamber where it is condensed in a fractional fashion. Normally a 3 tier system is used. The first two trays mostly comprise of diesel and the third one comprises of mainly kerosene and gasoline.

- Refining : These are then send into a refining center where these are refined into about 80% Oil, 15% gas and 5% ash.

Uses of the end products

Oil : The oil is further refined to be used in Industries and for transportation after being separated out into Diesel, Gasoline and Kerosene.

Gas : The gas produced is mainly reused to power the Pyrolysis process diminishing the requirements for the need of external supply of fuel.

Ash : The ash produced is used in making construction cement or sometimes as a catalyst.

Advantages and Disadvantages

Pyrolysis is an energy extensive process and the amount of energy required to extract oil is more than that of the obtained value thus can never be sustainable. But these methods will definitely reduce the Plastic pollution and lead to healthier environment. About 280 million tons of plastic is dumped into the environment every year and remain in nature for hundreds or even thousands of years. These stay in the biosphere, leaking poisonous elements and carcinogenic material. Recently there have been development of degradable plastic, but not much have been done to remove the non-degradable ones. This method gives us a scope in this field. Disposing plastic results in the expenditure of about 2 billion US dollars a year. If this is instead used to convert it into fuel, it would not only decrease the plastic level but also add value to the Energy industries.

My perspective on Energy : Instead of heating, if we can store the plastic deep underground, then would it be possible to convert it back into Oil using geothermal energy?

Note : Although this method reduces the net "Bad" environmental effects, it is necessary to include other other methods - such as Artificial Carbon Capture - to attenuate the emission of CO2 produced due to burning of the produced fossil fuel.

0 Comments